Whats the difference?Which one is better?

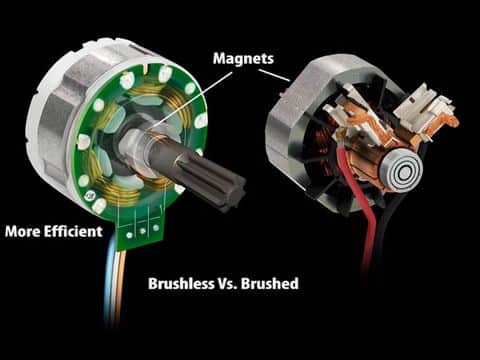

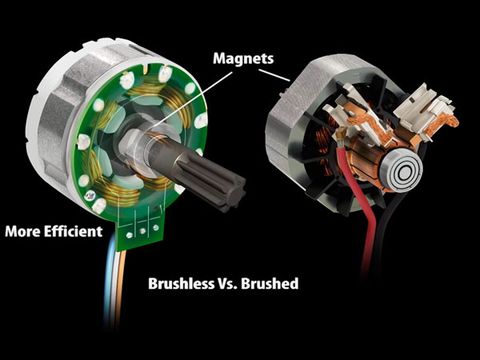

1.Brush Motor: Windings on rotor, magnets on stator

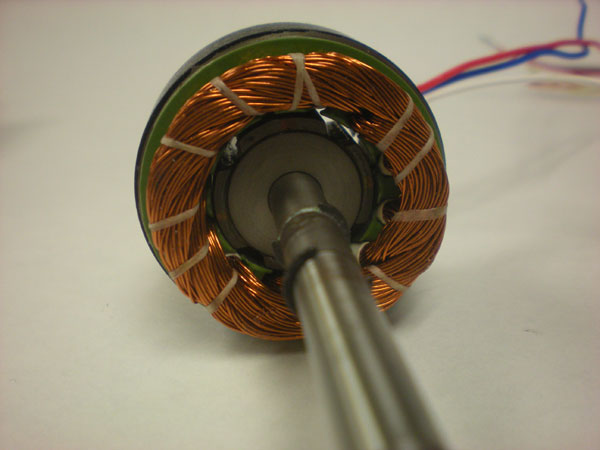

2. Brushless Motor: Windings on stator, magnets on rotor

Construction Differences

In the brushed motors, brushes are used to deliver current to the motor windings through commutator contacts. Brushless motors have none of these current-carrying commutators. The field inside a brushless motor is switched via an amplifier triggered by a commutating encoder, such as an optical encoder.

Windings are on the rotor (rotating part of motor) for brush motors and on the stator (stationary part of motor) for brushless motors.

By positioning the windings on the outside stationary portion of the electric motor, the need for brushes can be eliminated.

There are hints of brush motors being first developed in the 1830s, by Michael Faraday.

Brushed motor Advantages:

– Simplified wiring: Brush motors can be wired directly to DC power and control can be a simple as a switch.

– Low cost

Brushed Motor Disadvantages:

– Less efficient

– Electrically noisy: The switching action of the commutators constantly creating and breaking inductive circuits creates a great deal of electrical and electromagnetic noise.

– Lifespan: As they are in perpetual physical contact with the shaft, brushes and commutators wear out.

Brushless Motor vs Brush Motor Efficiency:

Brushless motors are typically 85-90% efficient whereas brushed DC motors are around 75-80% efficient.

This difference in efficiency means that more of the total power used by the motor is being turned into rotational force and less is being lost as heat.

Last Updated on August 27, 2021 by HelpDesk

Was this helpful?

0 / 0